Picking coffee in its most ripened stage is an art overseen by many. Unlike other fruit, coffee cherries have little ripening leeway after it’s picked. The deterioration begins shortly after the cherry is picked off the tree, and the sugar inside becomes starch almost immediately. Ripe coffee cherries must be picked carefully without disturbing the unripe coffee beans on the branch, a critical move to ensure quality coffee production.

Always wanted to know how your favourite coffee is made?

Hand picking the coffee beans

Our coffee beans being handpicked and only the best quality beans are selected. They are then placed in their respective gunny sacks ready for transportation.

Coffee Roasting

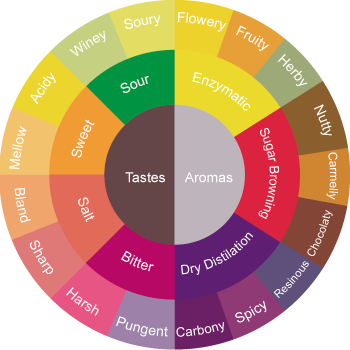

The beans being loaded into the roaster at temperatures above 200°c. The roasting process chemically and physically changes the bean – increasing volume, losing weight and moisture content, opening cells, releasing aromatics oils, and converting starches into sugars. Each coffee bean is roasted to an optimal level that accentuates its best characteristics to give a balance aroma, flavor, aftertaste, acidity and body.

Cupping test for coffee

Rock Sugar crystallization

The process of rock sugar crystallization to eliminate impurities creating fine, premium grade rock sugar. This premium rock sugar is used in Chek Hup’s coffee and tea instant beverages product to give a smooth texture, balance and cleaner cup profile.

The Mixing

Each batch is carefully mixed according to the Golden Ratio in the mixing process. The process involves adding the exact amount of rock sugar, creamer and coffee together to get the consistent quality, flavor and aroma in each cup of Chek Hup White Coffee.

The entire mixing process is enclosed to avoid any contaminants from the outside. The enclosed area features Stainless steel equipment, used throughout the process for cleanliness.

The Packaging Process

The process of packaging 3in1 coffee into sachets, counting the sachets and packing it into the outer pouch. The packaging material used in the packaging process is manufactured in house to ensure the highest quality and freshness.In addition, only environmental friendly packaging material is used.

Step 1

Step 2

Step 3

Step 4

The Finishing Touches

The batches that pass our quality and consistency sampling are then sealed and packed into their individual air tight bags and distributed to a store near you! The vivid coloured packages are definitely not to be missed!